Last Tuesday, another important milestone was reached at the construction site of the Base Oil Destillation Unit (BODU) at Shell Energy and Chemicals Park Rheinland when the first components of the electric process furnace were delivered.

The E-Heater, as it is known internally due to its mode of operation, plays a central role within the unit. Powered by renewable energy, it replaces the natural gas-fired heating systems previously used in such plants. Kraftanlagen Energies & Services, the general contractor responsible for constructing the new base oil plant, will now integrate the electric heater into the overall plant over the coming weeks.

“The e-heater is the heart of the entire plant,” explains Christian Wanghofer, head of the BODU project at Kraftanlagen Energies & Services. “It generates sustainable, CO₂-free heat, making it the first of its kind in this performance range for the petrochemical industry. Now that the delivery has been completed successfully, the assembly phase can begin. Despite facing a few challenges, we are still fully on schedule.”

A newly constructed base oil destillation unit at Shell Energy and Chemical Park Rheinland will enable the production of highquality, pure base oils that meet the highest standards from 2028 onwards. These oils can be used in medical and cosmetic applications, for example, or as more sustainable lubricants in the mobility sector. This is an important step in Shell Rheinland’s transformation journey towards becoming a production facility for low-carbon products. CO2

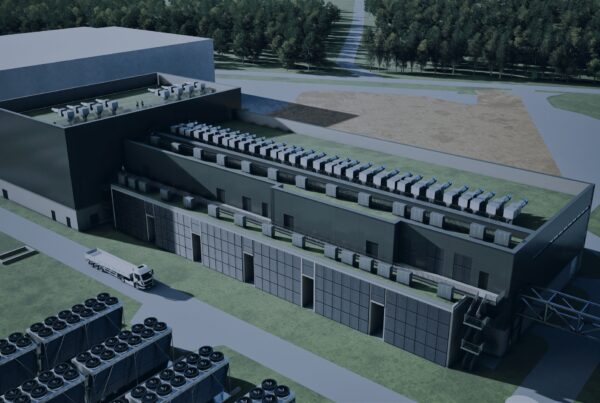

The new Base Oil Destillation Unit (BODU) at the Wesseling site will enable the production of highquality base oils. Last Tuesday, the first components of the central process furnace were delivered to the construction site.

©Shell Deutschland

Here you can download the press release as Pdf file.

Press contacts

Dr. Isabelle Werner +49 89 6237 387, isabelle.werner@kraftanlagen.com

Verena Treutlein +49 89 6237 627, verena.treutlein@kraftanlagen.com